Innovation Award Winner: Baker Brace

Benton Johnson

Principal

Skidmore, Owings & Merrill LLP, Chicago

Optimal Mega-Bracing for Tall Concrete Buildings

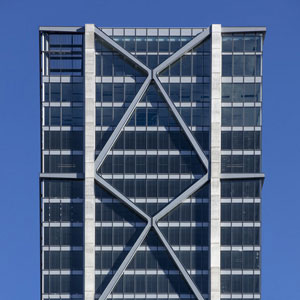

Multi-story “mega-bracing” is uncommon in concrete buildings, due to the complexity of concrete brace construction. Steel bracing has the additional complexity of time-dependent compression loading caused by shortening of the vertical concrete structure through creep and shrinkage. The structural solution for 100 Mount Street, a 38-story building that was designed as a concrete frame with post-tensioned floors and an offset concrete core that could result in significant torsional response under wind loads, was to add an exposed mega-bracing system along the opposite face of the building to balance the lateral resistance to wind loads. To curtail engineering issues associated with mega-bracing in a concrete building, a “Baker Brace” was configured to manage the torsional response of the building.

The “Baker Brace” is derived from discrete typology optimization and is similar to X-bracing, except the central node occurs at the three-quarters height instead of the mid-height of the bracing module. Long-term bracing stresses are relieved by introducing a sliding central node that releases self-stresses while maintaining lateral stiffness. This reduces steel tonnage for lateral loads, while also reducing the impact of vertical creep and shrinkage stresses. “Continuous member” bracing, with additional depth/stiffness at the mega-columns, improved the buckling resistance.

The central node was designed to release self-stresses of vertical elements, while maintaining the lateral load stiffness of the system. This was achieved by providing a horizontal sliding joint in the node which would resist vertical shearing forces while releasing horizontal compression forces from creep, shrinkage, or temperature loads. The sliding joint is provided with concealed elastomeric bearing pads in direct contact, sandwiched between structural steel “finger plates.” This reduced the design axial compression in the mega-braces by approximately 250 percent.